The 7-Minute Rule for Digital Printing

The 7-Minute Rule for Digital Printing

Blog Article

Digital Printing - The Facts

Table of ContentsSome Ideas on Digital Printing You Should KnowFacts About Digital Printing UncoveredGetting The Digital Printing To Work

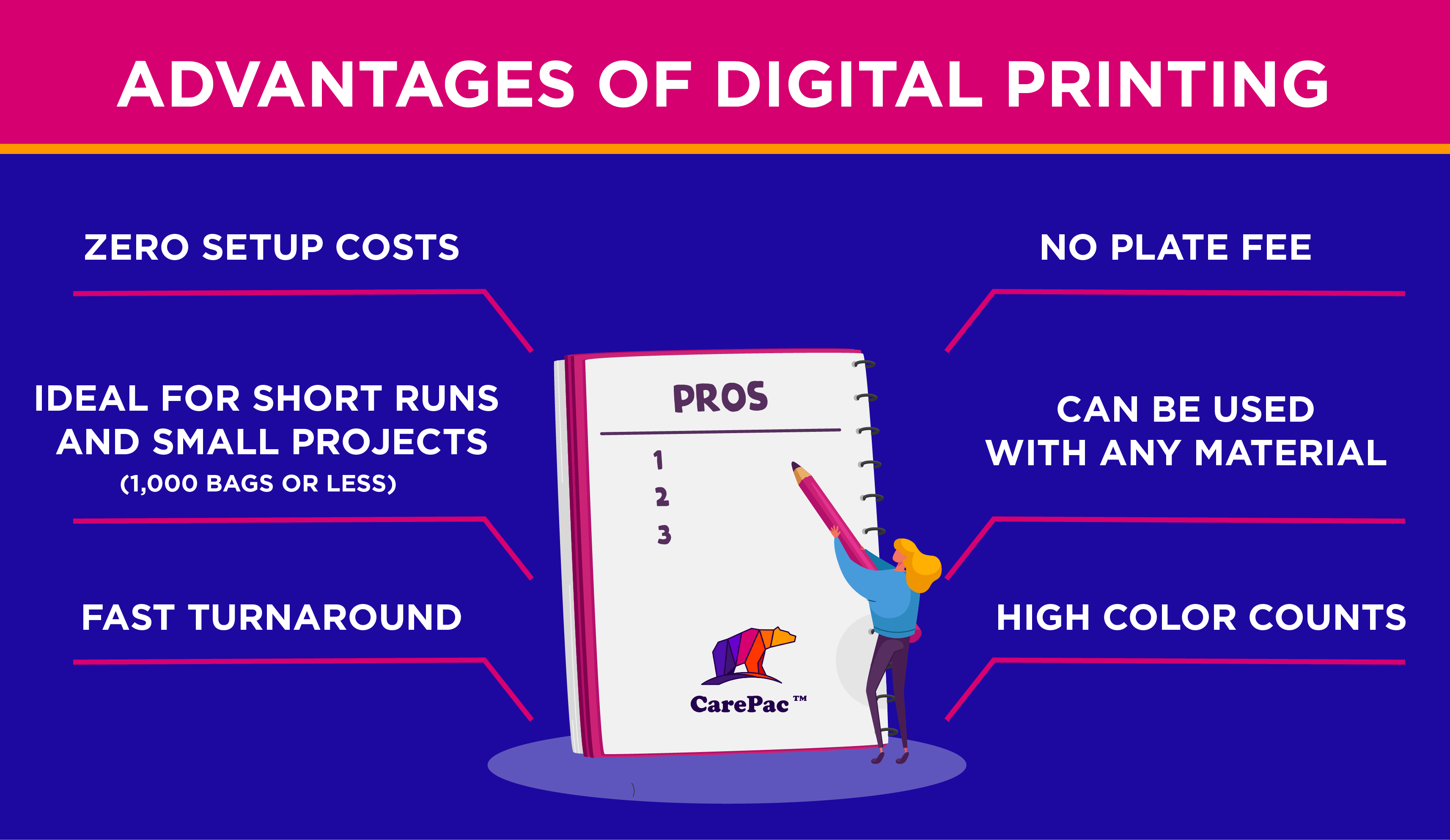

Digital printing also calls for very little setup. Below are the crucial ways in which electronic printing supports greener methods: One of the substantial ecological benefits of electronic printing is decreasing waste (Digital Printing). Traditional printing techniques, like lithographic printing, frequently waste considerable quantities of paper and ink during the setup stage.

Digital printing presses eliminate the demand for these plates, dramatically reducing configuration costs. Digital printing presses can incorporate variable information into your prints, which permits very customized marketing products (Digital Printing). By personalizing your advertising and marketing products, you can enhance interaction with prospective clients and enhance the opportunities of transforming them right into real consumers

Digital printing presses use exceptional shade consistency and accuracy, leading to higher top quality prints. With electronic printing, you can be sure that the shade of your prints will certainly be consistent from one print job to the following. Several years back, many customers did not accept direct-injection electronic printing since the high price. The purchase price of a set digital over here printing equipment is at the very least 150%of the standard printing and dyeing devices, which raises the.

All about Digital Printing

In order to stop deterioration of the nozzle, the ink for electronic printing is extra pricey than the ink for typical printing, and added ink filtration is necessary during the printing process. In electronic inkjet printing, the pattern is straight published on the textile, eliminating the plate making in rotary display printing. Yes, are extra expensive than traditional printing inks, but the electronic printing process can conserve ink usage.

Today, the electronic direct-injection printing equipment has actually gone from proofing to the stage of medium-sized and large-sized manufacturing. The digital direct-injection equipment has actually gone with the promotion duration and entered the development and maturity duration. Both printing houses and brand proprietors understand the growth potential of electronic printing, and agree to boost investment in digital printing. The print top quality can occasionally also rival that of offset printing. Digital printing is a lot more affordable for brief print runs hop over to these guys since it calls for much less pre-press activities and much less setup than countered printing. If a mistake in countered printing is not captured prior to the plates are made, it will be extremely expensive to make brand-new ones. While everybody sincerely really hopes that mistakes will be avoided, it is reasonable to prepare for their possible adjustment. In enhancement, its precision is really high. This makes certain uniformity in look across the board, minimizing the likelihood that any item will need to be my sources tossed out due to flaws. Guaranteeing home plates remain in area, the ink key is calibrated, and all the essential adjustments have been made is a taxing procedure when balanced out printing. Minimized pre-press steps suggest less time is needed to establish up the press. This leads to a marked velocity of turnaround time. When you require published products swiftly, this is an excellent alternative. Digital printing can be a lifesaver when you get an order in the nick of time.

Variable data printing, such as direct mail with individualized codes and addresses, is ideally fit for electronic printing. Digital quick printing only requires 4 steps of layout, review, printing and binding to get every little thing done. Digital quick printing has an unmatched advantage: print on demand.

Report this page